+86 13816508465

At Stream Pumps, quality and trust are at the heart of everything we do. We believe that the best products stem from straightforward processes executed with precision.

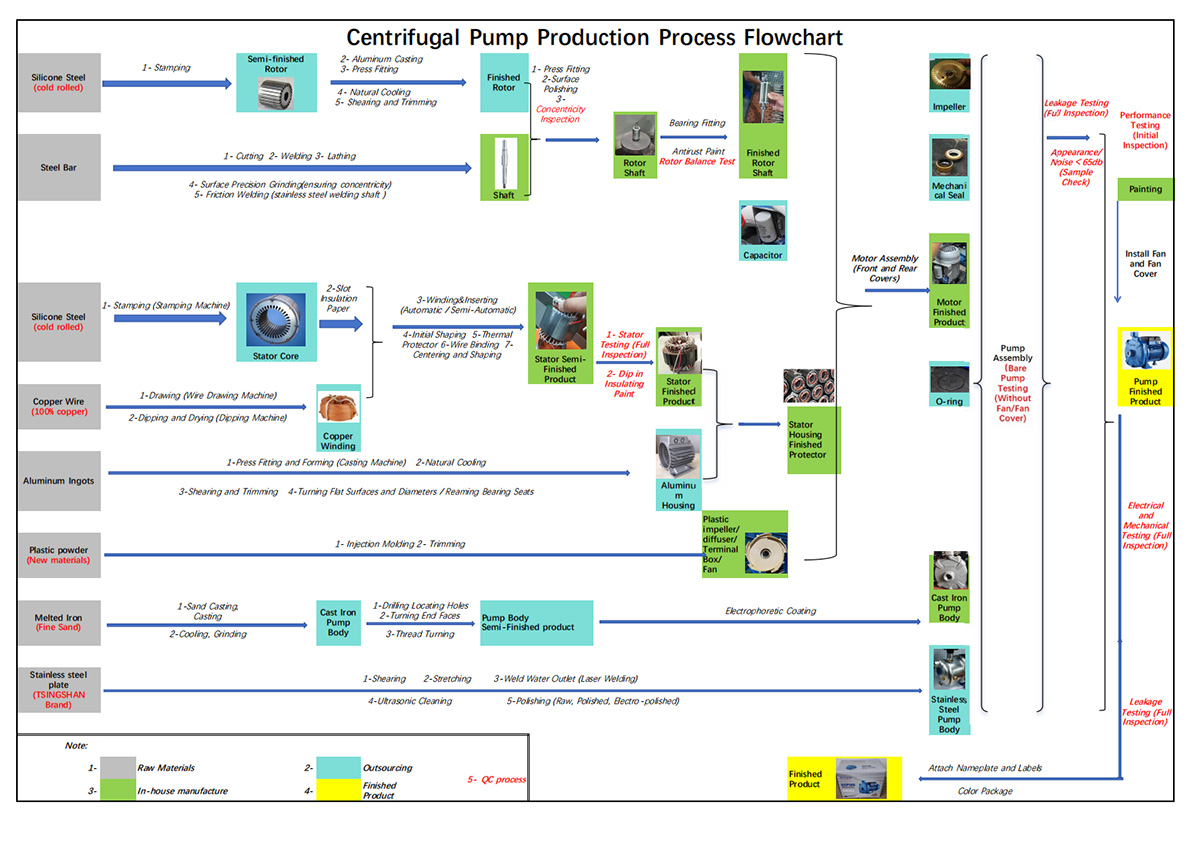

Today, we would like to pull back the curtain on our centrifugal pump production process, showcasing how we transform raw materials into reliable workhorses—simply and effectively.We believe that the best products come from straightforward processes executed with precision. Today, we're pulling back the curtain on our centrifugal pump production process, showing you how we turn raw materials into reliable workhorses—simply and effectively.

From Raw to Ready: A Visual Journey

Below is a simplified view of our production flowchart, highlighting the key steps that ensure every pump we make is up to our standards of uncomplicated excellence.

Material Selection: The Foundation

Quality begins with the right materials. We carefully select:

100% Copper Wire: Guarantees superior conductivity.

Cold Rolled Silicon Steel: Known for its strength and efficiency.

Fine Sand for Iron Casting: Ensures durability and effectiveness.

Branded Stainless Steel Sheets: Offers reliability and longevity.

Each material is chosen for its robustness and reliability, forming the backbone of our pumps.

Fine Machining: The Art of Precision

Using advanced CNC machining techniques, we transform raw materials into semi-finished parts. Precision in this stage is crucial, ensuring that each component fits and functions flawlessly. Our processes of press fitting and turning refine parts to exact specifications, ultimately enhancing the pump’s performance and longevity.

Test Procedure: The Guardian of Quality

No part is considered complete without passing our rigorous inspections.

We evaluate for:

Dynamic and Static Balance of rotors and stators

Concentricity Test of rotors’shaft

Leakage Test for hydraulic part

Full Electrical Test and Performance Test

Endurance Test

These critical factors ensure that every pump performs stably, consistently, and safely.

Assembly: Bring Components Into Life

Careful assembly brings our pump to life. Each part is meticulously put together and tested to ensure seamless operation and reliability. Our extensive experience enhance the trustworthiness of the final product.

Final Touches: Polishing the Gem

Quality extends beyond internal components. We focus on external treatments such as:

Anti Rust Paint

Electrophoresis Coating

Polishing

Detailed Painting

Protective Packaging

These finishing touches, though seemingly minor, significantly extend the product's service life while making it visually appealing at first glance.

Our Promise: Consistent Quality

At Stream Pumps, we're committed to making pumps that are reliable, durable, and straightforward. Our production process is designed to deliver consistent quality in every pump we make. By sharing our production process, we're not just showing you how it's done—we're building trust. We want you to know that when you choose our pumps, you're getting the best we have to offer.

Interested in learning more? Visit our website for detailed product solutions, high-resolution images and videos that take you through each step of our production process.

Previous: Comprehensive Customer Support: Powering Your Success

Next: None

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS