+86 13816508465

Pump Troubleshooting

Nov. 09, 2023

If you're experiencing difficulties with your water pump not starting, one possible reason could be an improper selection of the pressure controller. In this article, we will dig into the working principle of the pressure controllers, as well as offer installation tips to help you resolve the common issues.

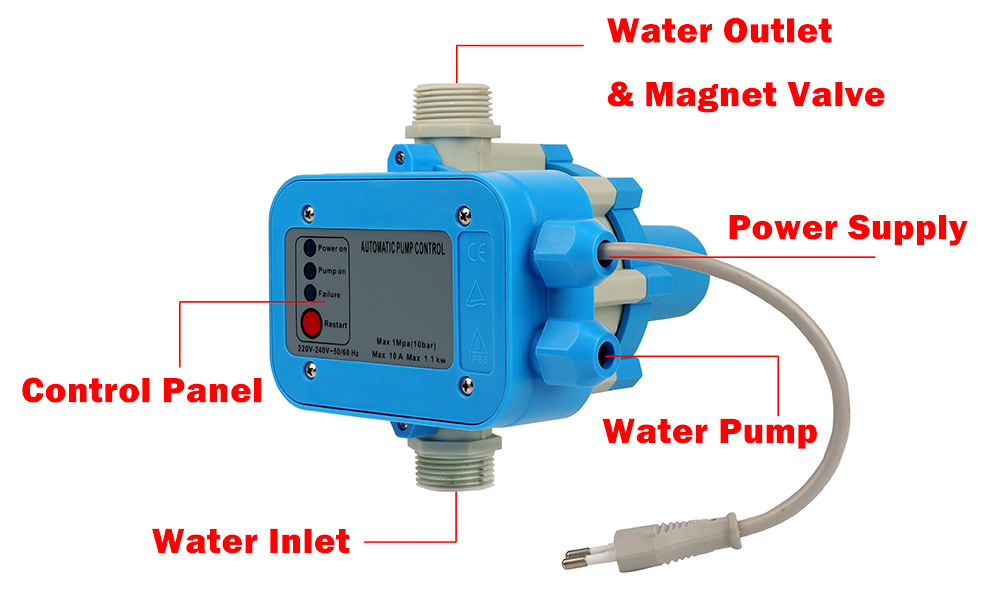

Pressure controller plays a crucial role in regulating household pump operation by sensing water pressure and activating the pump.

Let’s explore what it is and how it works so as to easily address some problems when it doesn’t work.

1-Product Structure

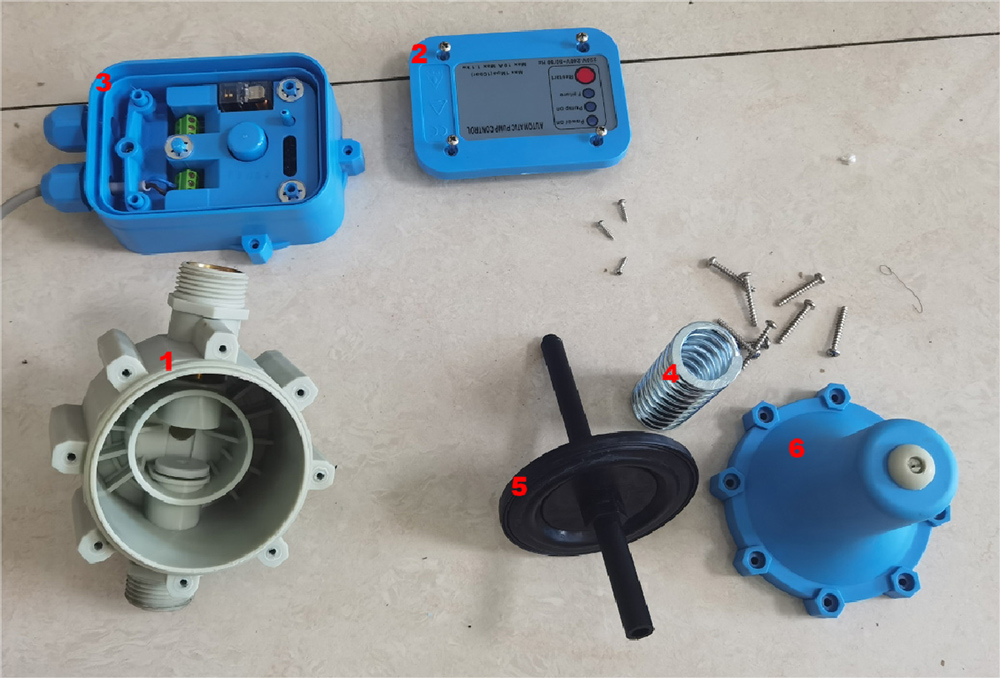

Exploded View:

1.Main Body (includes a magnet copper check valve and a flow switch)

2.Upper Cover

3.Circuit Board

4.Spring

5.Diaphragm

6.Back Cover

2-Working principle

1.1 Pump On:

When the user turns on a faucet, the pressure inside the pipe decreases, triggering the activation of the water pump. This happens when the pressure inside the pipe reaches the preset starting pressure of the controller or when the water flow at the controller's outlet lifts the copper valve.

TIPS: In buildings with significant height differences, there is a possibility of water hammer pressure exceeding the startup pressure of the controller, resulting in a slow startup or failing to start.

1.2 Pump Off:

When the user closes the faucet, the flow valve at the controller's outlet closes as water flow stops. After the copper valve returns to its sensing point, the water pump stops running following a 10-15 second period of pressure holding detection.

TIPS: It's important to note that under certain circumstances, such as water pipe leakage, foreign objects blocking the flow valve, or excessive bends in the water pipe, the pump may not be able to shut down as per this principle.

1.3 Cases when the pump doens't start

Understanding the starting principle, now we can figure out why the pump cannot start in certain situations. When the pump is lifting water from ground level to higher floors, especially when the floor height exceeds the pressure controller's required vertical height, it may prevent the pump from starting or cause it to stop at incorrect pressure levels.

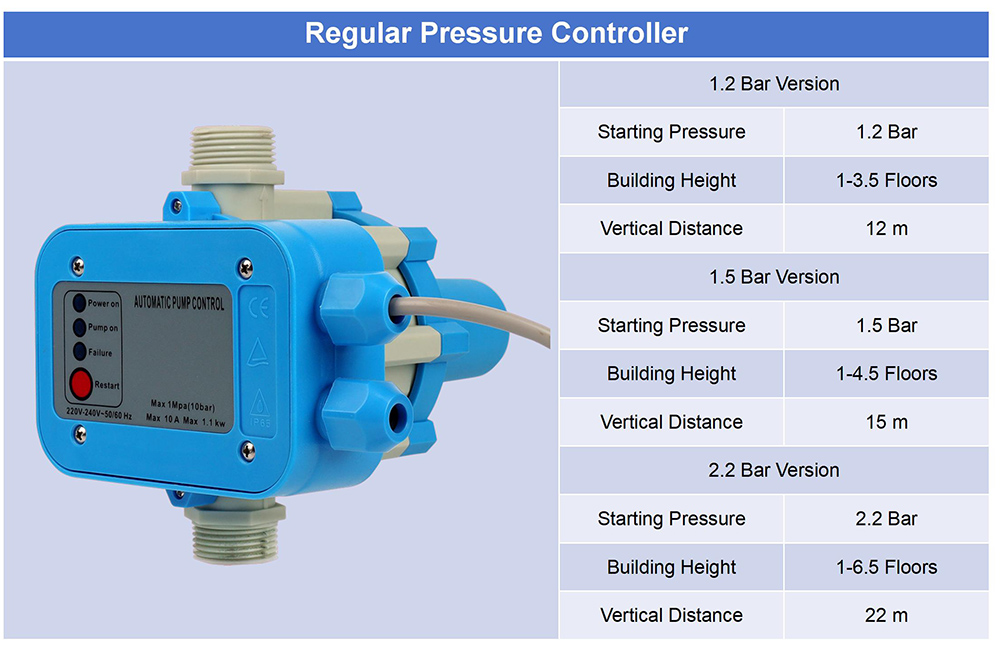

1.4 Limitation of regular pressure controllers

The regular pressure controller has a fixed or adjusted starting pressure, but mostly around 1.2-2.2bar. It leads to the restrictions that the controller only work under certain building heights. Once the building is higher than the limitations, it could lead to non-start of the pump. For example, if you choose a pump controller with starting pressure of 1.5bar, then this controller can only with a pump with maximum 1.1kw power, and working height below 15m.

To avoid these problems, it's important to carefully assess your system's water pressure needs and select a pressure controller with a suitable control range.

3-Installation Tips

Proper installation of the pressure controller is crucial for optimal performance.

Consider the following tips which can avoid many problems:

1.When installing a regular pressure controller, it must be installed in a vertical position according to the arrow indication on the controller's inlet and outlet interface. Horizontal or lying installations are not allowed, as they will prevent automatic control( Because the magnet valve at water outlet requires certain flow to lift up and down).

2.The controller must be used in conjunction with a water pump. It should be installed at the pump's water outlet or on the water pipe. When installing the controller's water outlet, special attention should be paid to preventing any foreign objects from entering the internal copper valve of the flow valve. During the application of sealant tape, ensure that it doesn't obstruct the free movement of the copper valve in the water outlet. Care should be taken to avoid uncured adhesive entering the internal copper valve of the flow valve.

3.When using the controller in complex piping systems with multiple bends in the water outlet, the controller's water outlet should not have a direct 90-degree bend. It should be elevated by approximately one meter before making the bend. If it is not possible to elevate before the bend, the excessive bends in the piping may cause a vortex effect at the water outlet, resulting in the flow valve being unable to return to its normal position and causing the pump to remain operational even when there is no water usage.

4.When using the controller in buildings with significant height or beyond the effective control height specified in the selection table, it may cause slow startup or failure to start. This is due to water hammer pressure generated by the height of the building exceeding the startup pressure of the controller. To address this issue, either choose a controller with a higher startup pressure or install a one-way check valve with a sealing function on the vertical main pipe to prevent water hammer pressure from entering the controller. Additionally, try to install the controller at a higher position and farther away from the water outlet.

5.When using the controller with a suction well, a check valve must be installed in the suction pipe to ensure a sealed system. It is crucial to maintain absolute sealing of the suction pipe, and the pump and suction pipe must be filled with water before each use. Due to the unique characteristics of drawing water from a well, the system may frequently experience alarm shutdown or failure to stop due to pipe sealing issues and pump chamber cavitation.

6.When using a relatively small water pump, pay special attention to the selection of the controller. For a pump head of 15 meters, only a controller with a 0.5bar startup pressure can be used. Typical water pumps like hot water circulation pumps below 10m head fall into this category. Even with this setup, there may still be instances where the controller triggers an alarm shutdown due to low pump pressure and flow, especially when the user's water flow increases. Therefore, it is recommended to calculate the water flow required for the user to ensure compatibility with the selected pump, and not neglect the relationship between flow, head, and curve changes, even if it is for boosting water pressure from the rooftop. This will prevent unnecessary after-sales service.

7.After connecting the input and output wires to the controller, close the external panel and tighten the screws. Then, press the reset/restart button on the panel to check if it can be pressed smoothly. If it cannot be pressed, loosen the four screws on the panel until the button can be pressed freely. Otherwise, the controller will be unable to stop properly.

Conclusion:

By understanding the limitations of pressure controllers, recognizing common problems, and adhering to proper installation tips, you can troubleshoot and resolve the issue effectively.

Previous: HYDROBOX900 Troubleshooting Guide

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS