+86 13816508465

Pump Troubleshooting

Mar. 05, 2024

Welcome to the HYDROBOX900 Troubleshooting Guide, your go-to resource for resolving common issues with Stream HYDROBOX900 booster pump.

This guide is designed to help you quickly identify and address any operational challenges, ensuring your pump continues to perform at its best.

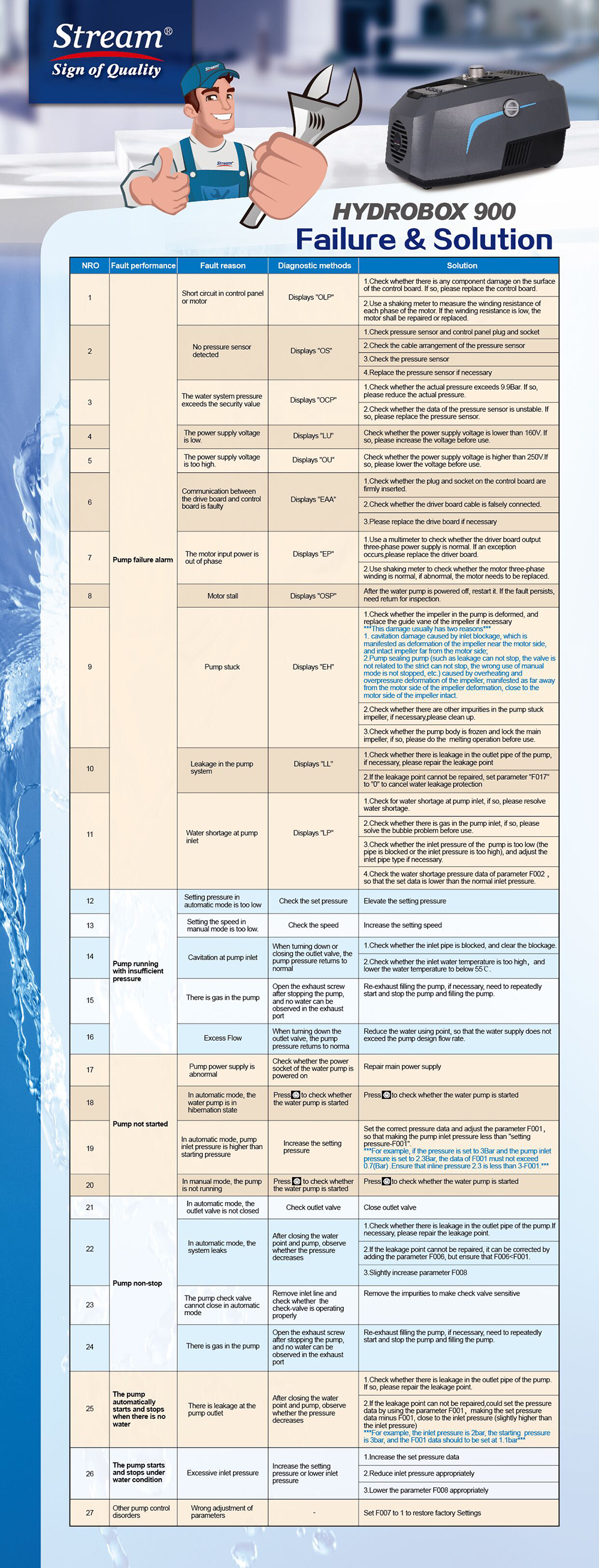

HYDROBOX900 failure and solution | ||||

NRO | Fault performance | Fault reason | Diagnostic methods | Solution |

1 | Pump failure alarm | Short circuit in control panel or motor | Displays 【OLP】 | 1.Check whether there is any component damage on the surface of the control board. If so,please replace the control board. |

2.Use a shaking meter to measure the winding resistance of each phase of the motor. If the winding resistance is low, the motor shall be repaired or replaced. | ||||

2 | No pressure sensor detected | Displays 【OS】 | 1.Check pressure sensor and control panel plug and socket | |

2.Check the cable arrangement of the pressure sensor | ||||

3.Check the pressure sensor | ||||

4.Replace the pressure sensor if necessary | ||||

3 | The water system pressure exceeds the security value | Displays 【OCP】 | 1.Check whether the actual pressure exceeds 9.9Bar. If so, please reduce the actual pressure. | |

2.Check whether the data of the pressure sensor is unstable. If so, please replace the pressure sensor. | ||||

4 | The power supply voltage is low. | Displays【LU】 | Check whether the power supply voltage is lower than 160V. If so, please increase the voltage before use. | |

5 | The power supply voltage is too high. | Displays 【OU】 | Check whether the power supply voltage is higher than 250V.If so, please lower the voltage before use. | |

6 | Communication between the drive board and control board is faulty | Displays 【EAA】 | 1.Check whether the plug and socket on the control board are firmly inserted. | |

2.Check whether the driver board cable is falsely connected. | ||||

3.Please replace the drive board if necessary | ||||

7 | The motor input power is out of phase | Displays 【EP】 | 1.Use a multimeter to check whether the driver board output three-phase power supply is normal. If an exception occurs,please replace the driver board. | |

2.Use shaking meter to check whether the motor three-phase winding is normal, if abnormal, the motor needs to be replaced. | ||||

8 | Motor stall | Displays 【OSP】 | After the water pump is powered off, restart it. If the fault persists, need return for inspection. | |

9 | Pump Stuck | Displays 【EH】 | 1.Check whether the impeller in the pump is deformed, and replace the guide vane of the impeller if necessary | |

2.Check whether there are other impurities in the pump stuck impeller, if necessary,please clean up. | ||||

3.Check whether the pump body is frozen and lock the main impeller, if so, please do the melting operation before use. | ||||

10 | Leakage in the pump system | Displays 【LL】 | 1.Check whether there is leakage in the outlet pipe of the pump, if necessary, please repair the leakage point | |

2.If the leakage point cannot be repaired, set parameter 【F017】 to 【0】 to cancel water leakage protection | ||||

11 | Water shortage at pump inlet | Displays 【LP】 | 1.Check for water shortage at pump inlet, if so, please resolve water shortage. | |

2.Check whether there is gas in the pump inlet, if so, please solve the bubble problem before use. | ||||

3.Check whether the inlet pressure of the pump is too low (the pipe is blocked or the inlet pressure is too high), and adjust the inlet pipe type if necessary. | ||||

4.Check the water shortage pressure data of parameter F002 ,so that the set data is lower than the normal inlet pressure. | ||||

12 | Pump running with insufficient pressure | Setting pressure in automatic mode is too low | Check the set pressure | Elevate the setting pressure |

13 | Setting the speed in manual mode is too low. | Check the speed | Increase the setting speed | |

14 | Cavitation at pump inlet | When turning down or closing the outlet valve, the pump pressure returns to normal | 1.Check whether the inlet pipe is blocked, and clear the blockage. | |

2.Check whether the inlet water temperature is too high ,and lower the water temperature to below 55℃. | ||||

15 | There is gas in the pump | Open the exhaust screw after stopping the pump, and no water can be observed in the exhaust port | Re-exhaust filling the pump, if necessary, need to repeatedly start and stop the pump and filling the pump. | |

16 | Excess Flow | When turning down the outlet valve, the pump pressure returns to norma | Reduce the water using point, so that the water supply does not exceed the pump design flow rate. | |

17 | Pump not started | Pump power supply is abnormal | Check whether the power socket of the water pump is powered on | Repair main power supply |

18 | In automatic mode, the water pump is in hibernation state |

|

| |

19 | In automatic mode, pump inlet pressure is higher than starting pressure | Increase the setting pressure | Set the correct pressure data and adjust the parameter F001,so that making the pump inlet pressure less than 【setting pressure-F001】. | |

20 | In manual mode, the pump is not running |

|

| |

21 | Pump Non-stop | In automatic mode, the outlet valve is not closed | Check outlet valve | Close outlet valve |

22 | In automatic mode, the system leaks | After closing the water point and pump, observe whether the pressure decreases | 1.Check whether there is leakage in the outlet pipe of the pump.If necessary, please repair the leakage point. | |

2.If the leakage point cannot be repaired, it can be corrected by adding the parameter F006, but ensure that F006<F001. | ||||

3.Slightly increase parameter F008 | ||||

23 | The pump check valve cannot close in automatic mode | Remove inlet line and check whether the check-valve is operating properly | Remove the impurities to make check valve sensitive | |

24 | There is gas in the pump | Open the exhaust screw after stopping the pump, and no water can be observed in the exhaust port | Re-exhaust filling the pump, if necessary, need to repeatedly start and stop the pump and filling the pump. | |

25 | The pump automatically starts and stops when there is no water | There is leakage at the pump outlet | After closing the water point and pump, observe whether the pressure decreases | 1.Check whether there is leakage in the outlet pipe of the pump. If so, please repair the leakage point. |

2.If the leakage point can not be repaired,could set the pressure data by using the parameter F001,making the set pressure data minus F001, close to the inlet pressure (slightly higher than the inlet pressure) | ||||

26 | The pump starts and stops under water condition | Excessive inlet pressure | Increase the setting pressure or lower inlet pressure | 1.Increase the set pressure data |

2.Reduce inlet pressure appropriately | ||||

3.Lower the parameter F008 appropriately | ||||

27 | Other pump control disorders | Wrong adjustment of parameters | - | Set F007 to 1 to restore factory Settings |

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS