+86 13816508465

Pump Troubleshooting

Oct. 16, 2024

The abnormal pump performances could cause Reduced pump efficiency, increase downtime and finally damage to the pump or related equipment.

Check out below causes and solutions for a quick troubleshooting.

1.Not Air Vented

Reason:

The water pump is used for the first time or after the water is cut off, not exhaust air

Manifestation:

The water pump does not pump water or the water output and water pressure are insufficient.

How to Judge:

Open the exhaust screw, there is air overflow.

Close the outlet valve, the pump head is not enough.

Solution:

Exhaust completely.

2.Pump Cavitation

Reason:

When the pump absorbs water, the water vaporizes due to the pressure drop.

Manifestation:

Insufficient water flow and head.

Accompanied by abnormal noise.

How to Judge:

Turn off the outlet valve to let the water pump run at 0 flow and reach the full head point, and the noise disappears.

Solution:

Check the inlet pressure, the constant pressure value or the water level is reasonable.

Check the liquid temperature and reduce the inlet liquid temperature appropriately.

Reduce the resistance of the inlet pipe, increase the pipe dia. or clean the filter.

Reduce the opening of the outlet valve to avoid overcurrent operation.

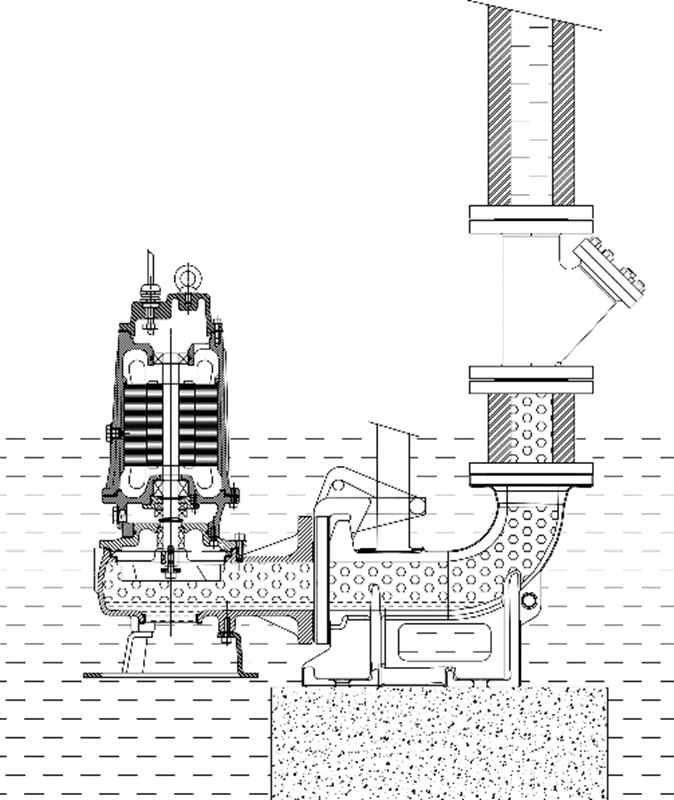

3.Air Lock (for sewage pumps)

Reason:

The back end of the outlet check valve is full of water, the air inside the pump body cannot be released or compressed, and the water level cannot touch the impeller.

Manifestation:

The water pump runs but does not drain water.

How to Judge:

Shake the water pump or loosen the lower connection of the check valve

Let some of the air escape and the pump will run fine.

Solution:

Add an exhaust hole at the lower end of the check valve.

(Remark: If the hole is too large, the pump performance will be reduced largely. If the hole is too small, it will be easily blocked by anhydrous impurities.)

Always keep the pump stop liquid level higher than the water pump suction.

4.Air In The Pump Body

Reason:

Air is not exhausted fully or system air enters the pump body.

Manifestation:

Water and Flow head drops, pressure fluctuates.

With vibration and noise

How to Judge:

Close the valve and the pump cannot reach the full head, and the pressure gauge fluctuates.

Solution:

Exhaust again, and check the cause of air occurring in the system, and solve it from the system.

5.Reverse (three-phase motor)

Reason:

The wiring of the three-phase motor is wrong.

Manifestation:

Motor rotation is opposite to the marked direction.

Solution:

Replace any two live wires.

If a frequency converter is involved, the wiring between the frequency converter and the motor needs to be replaced.

6.Impeller Drop

Reason:

Water hammer

The water pump has reversed for a long time.

Manifestation:

No flow and head

There is abnormal noise in the pump body.

How to Judge:

Disassemble the pump for inspection.

Solution:

Reassemble the impeller and check the direction of the pump rotation.

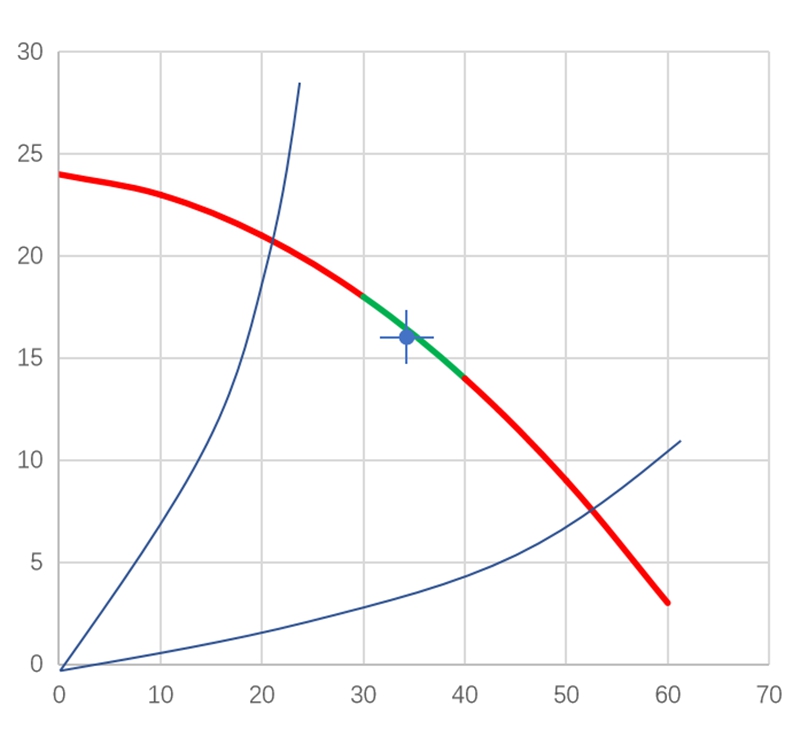

7.System Resistance Does Not Match

Reason:

The system resistance does not match the design value, which is either too large or too small.

Manifestation:

The pump head deviates from the design value.

Flow, head, power and current conforms to the original pump curve.

How to Judge:

Adjust the valve opening and try to adjust the system resistance curve.

Solution:

Adjust the valve opening.

Adjust outlet pipe diameter.

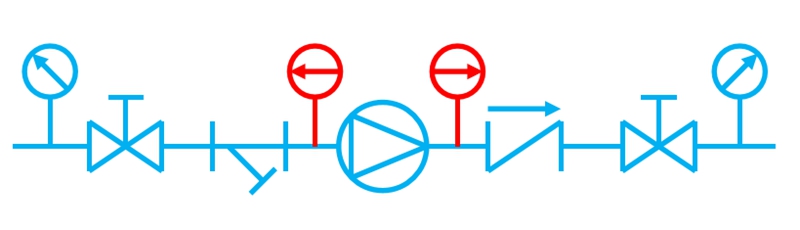

8.Performance Checkpoint Error

Reason:

The pressure gauge or sensor is installed in the wrong place.

Manifestation:

The pressure cannot reach the rated point.

How to Judge:

After closing the remote valve, the pressure can rise to full head (consider height difference).

Solution:

Readjust the pressure point.

Using KV values to calculate and correct the pressure values.

9.Setting Error (Frequency Conversion)

Reason:

Inverter parameter settings are wrong, such as constant voltage value, maximum speed, power limit.

Manifestation:

The flow and head of the water pump does not meet the standard, but the performance conforms to the curve.

How to Judge:

Switch to power frequency mode to run the pump and test hydraulic performance.

Solution:

Check inverter parameters and correct parameter settings.

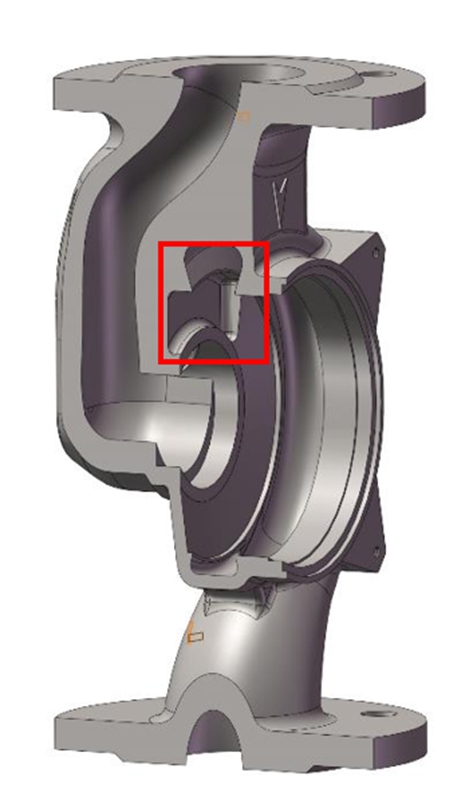

10.Impeller Assembly Error

Reason:

The impeller has axial displacement due to the the wrong installation sequence or wrong positioning of the bushing. And it causes backflow from the suction port.

Manifestation:

Insufficient flow and head

How to Judge:

Disassemble the pump for inspection.

Solution:

Remove and reassemble the impeller.

11.Impeller Damage

Reason:

Impeller is damaged due to impurities entering or cavitation.

Manifestation:

Insufficient flow and head, inconsistent with the performance curve.

With vibration or noise

How to Judge:

Disassemble and check the water pump.

Solution:

Replace the impeller

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS