+86 13816508465

Pump Solutions

Apr. 18, 2025

The Art of Music Fountains

Modern music fountains transform water into a dynamic canvas of light and motion, synchronized with sound to create mesmerizing performances. These systems blend hydraulic precision, advanced control algorithms, and artistic choreography, making them iconic installations in diverse settings:

Urban Landmarks: City plazas, waterfront developments, and architectural focal points.

Entertainment Hubs: Theme parks, luxury resorts, and cultural tourism destinations.

Global Events: Olympic ceremonies, international expos, and festival spectacles.

The global market for music fountain systems is expanding rapidly, driven by smart city initiatives and the growing demand for experiential tourism, with an estimated annual growth rate of 8.5% (2023–2030).

1. Pump Selection Guide

Pump Types

Submersible Pumps :

Application: Ideal for dynamic water displays requiring silent operation and corrosion resistance. Suitable for medium-height performances (up to 80m).

Key Features: Fully submersible design, energy-efficient motors, and 316L stainless steel construction.

Vertical Multistage Centrifugal Pumps:

Application: Engineered for high-precision, large-scale installations with ultra-tall water columns (100m+).

Key Features: Integrated variable frequency control and modular design for easy maintenance.

High-Pressure Plunger Pumps:

Application: Specialized systems such as water screen projections requiring extreme pressure (15–30MPa).

Technical Parameters

Flow Calculation:

Total Flow (Q) = Sum of all nozzle flow rates × Safety Factor (1.2–1.5).

Example: For a complex pattern with multiple nozzles, calculate peak demand and add redundancy.

Head Requirement:

H = Nozzle Design Height + Pipe Friction Loss + 15% Safety Margin.

Tip: Use computational fluid dynamics (CFD) to optimize pipe routing and minimize losses.

Power Optimization:

Select pumps with high-efficiency motors (η ≥ 85%) and variable frequency drives (VFDs) to adapt to real-time performance demands.

Selection Process

Define performance objectives: maximum height, water pattern complexity, and synchronization accuracy.

Model the hydraulic system using 3D simulation tools to identify flow and pressure requirements.

Choose VFD-compatible pumps for precise speed control (±0.5% accuracy).

Incorporate 25% capacity redundancy to accommodate peak operational loads.

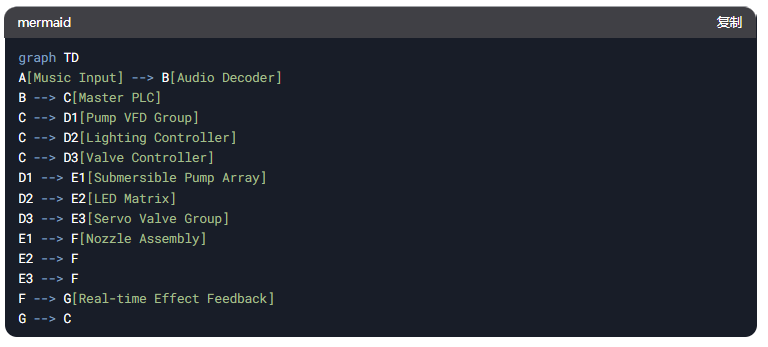

2.Integrated System Architecture

Pump Control | VFD Integration |

Lighting | P68 Submersible LED Fixtures |

Motion Control | High-Speed PLC with EtherCAT Protocol |

Water Treatment | Multi-Stage Filtration & UV Sterilization |

3. Implementation Guidelines

Hydraulic Design

Optimize nozzle placement to avoid hydraulic interference.

Implement anti-cavitation measures (NPSH margin ≥ 1m).

Synchronization

Achieve audio-to-water latency < 100ms

Compensate for signal delays in distributed nozzle clusters.

Safety & Reliability

Dual redundant control networks with automatic failover.

Emergency drainage is activated within 3 seconds via automated valves.

4. Case Study: Urban Plaza Installation

Component | Specification | Quantity |

Main Pumps | STREAM CDL Series (45m³/h, 45m head) | 8 units |

Variable Frequency Drives | ABB ACS880-01-072A-3 | 8 sets |

Adjustable Swivel Nozzles | 304 Stainless Steel, Φ50-200mm | 120 units |

Control Cabinet | Siemens S7-1500 + TPC7062Ti | 2 sets |

Submersible Lighting | Philips ColorReach Powercore | 400 units |

Water Screen Projection | Laser Projector (30,000 lumens) | 2 sets |

Performance Metrics:

Synchronization accuracy: ±50ms audio-to-water alignment.

Energy efficiency: 30% reduction via VFD optimization.

Maintenance interval: 12-month service cycle.

5. Maintenance & Sustainability

Winterization: Dry system purge with moisture content <5%.

Preventive Checks:

Monthly: Inspect seals, bearings, and electrical connections.

Annual: Recalibrate sensors and valve actuators.

Eco-Friendly Operation:

Closed-loop water recycling with <5% weekly replenishment.

Solar-powered lighting options available.

This solution delivers unparalleled precision in water choreography, robust reliability for continuous operation, and seamless scalability for projects of all sizes. For optimal results, conduct phased testing starting with a pilot subsystem before full deployment.

Previous: None

Next: Affordable Flood Prevention: Lightweight Pump & Basket Drainage Kit

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS