+86 13816508465

Pump Solutions

Jan. 04, 2024

Product Description

The SCM Close-coupled submersible pump is a compact and powerful pump designed for use in residential and commercial well applications. It has a 5-inch diameter and close-coupled design that makes it easy to install and maintain.The pump is capable of efficiently and reliably pumping water from wells,reservoirs,and other sources.

Problem Statement

Recently, our company received claims of water leakage in SCM motors, which has drawn significant attention to our production. These pumps were being used for submerged applications in high water depths, supplying water for long-distance agricultural irrigation. Upon inspection, it was discovered that the motors had experienced water leakage, leading to burnouts. After discussions with customers and technicians, it was determined that the root cause of the problem was the failure of mechanical seals under super high working pressure.

Solution Provided

To address the issue and prevent further water leakage incidents, two key upgrades were implemented for this unique application.

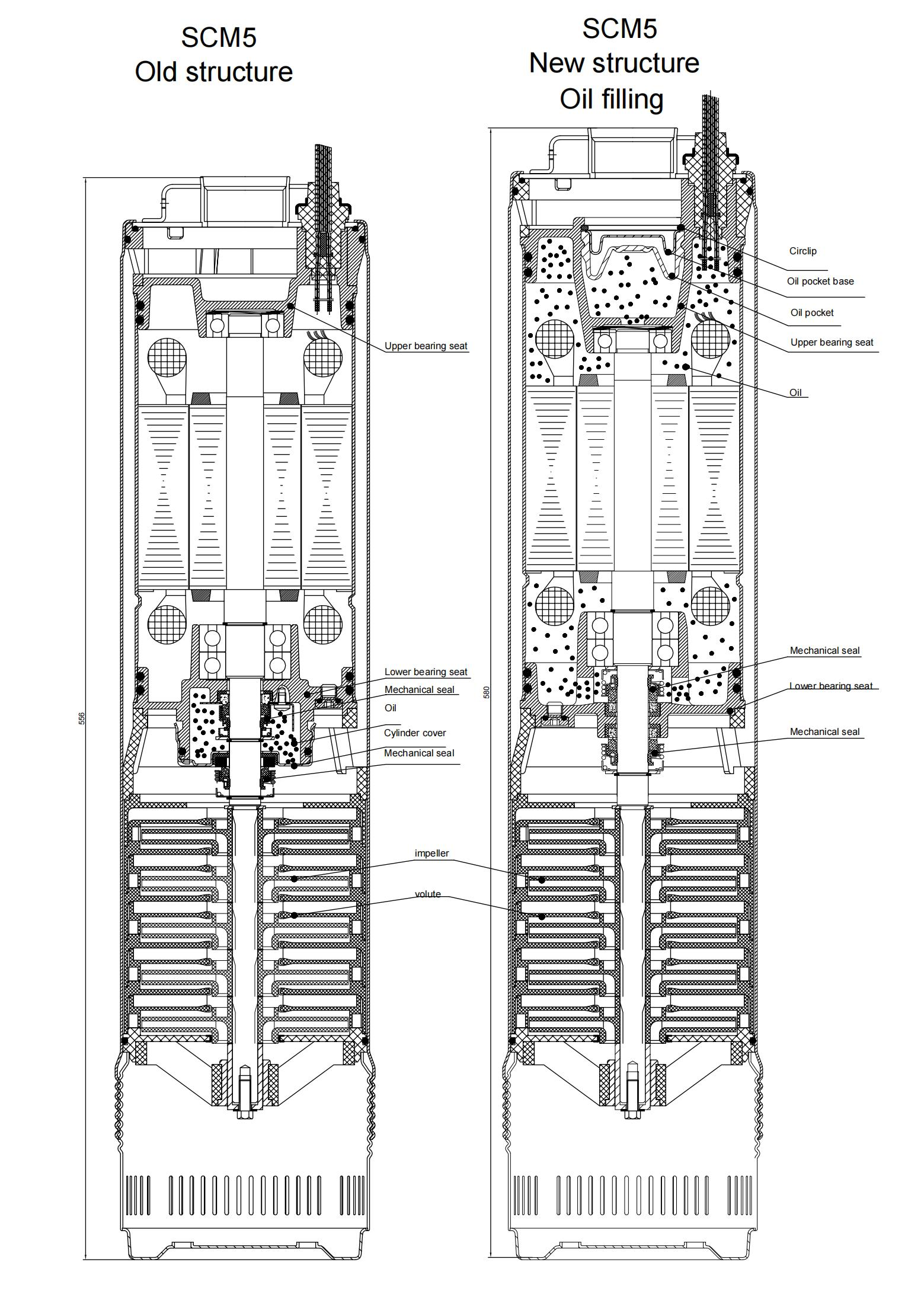

1-Motor Design Upgrade:

The motor design was changed from a dry motor to an oil-filled motor, offering the following advantages:

a) Lower temperature rise within the motor due to internal oil filling.

b) Improved lubrication at bearing locations, resulting in smoother operation and an extended bearing lifespan.

c) Enhanced pressure resistance and the ability to operate at greater water depths due to the motor's oil-filled bladder structure.

2-Mechanical Seal Specification Upgrade:

To enhance pressure resistance and reliability, the mechanical seal specifications were upgraded as follows:

a) The internal mechanical seal specification of the oil cylinder was changed from 108-16 (28N) to 108-16 (45N), while keeping the installation height unchanged.

b) The external mechanical seal specification was changed from 301-16 (working height 21, spring force 28N) to 70-16 (working height 22.5, spring force 52N), with a stationary ring at a diameter of 33mm.

c) The stationary ring was bonded to the oil cylinder cover using adhesive, eliminating the need for a stainless steel gasket during the installation of the external mechanical seal.

Results and Benefits

The implementation of these upgrades effectively addressed the water leakage issue in SCM motors. The oil-filled motor design significantly reduced temperature rise, improved lubrication, and enhanced pressure resistance, enabling the motors to operate reliably in high water depths. The upgraded mechanical seal specifications provided increased pressure resistance and reliability, preventing water leakage and extending the lifespan of the motors. These improvements not only resolved the immediate problem but also increased customer satisfaction and confidence in our product's performance for similar demanding applications.

Overall, by identifying the root cause and implementing targeted upgrades, our company successfully mitigated the issue of water leakage in SCM motors, ensuring reliable operation and customer satisfaction in high water depth and long-distance agricultural irrigation applications.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS