+86 13816508465

Jul. 13, 2023

When it comes to motor production for water pumps, there are two common types of wire used: copper wire and aluminum wire. Copper wire motors have traditionally been the standard, due to their superior electrical conductivity, heat resistance, and durability. However, in recent years, many manufacturers have started using aluminum wire motors as a cost-saving measure. While aluminum wire is cheaper than copper wire, it is not as efficient at conducting electricity and can have a shorter lifespan.

So, what are the differences between copper and aluminum motors?

Copper wire motors have a higher electrical conductivity, which means they can more efficiently conduct electricity and generate less heat during operation. This makes them ideal for high-performance pumps that require a lot of power, such as deep well pumps, submersible pumps, and centrifugal pumps. They are also more durable and have a longer lifespan, making them a more reliable choice for long-term use.

Aluminum wire motors, on the other hand, are typically less expensive to produce than copper wire motors. They are often used in low to medium-power pump. Aluminum wire is lighter than copper wire, which can make the motor more lightweight and easier to handle. However, aluminum wire is also less durable than copper wire and can break down more quickly over time, leading to a shorter lifespan for the motor.

In summary, copper-wire motors are more efficient, provide higher power output, and have better durability and reliability than aluminum-wire motors.

However, aluminum-wire motors are a cost-effective option for low-power and low-load applications. It is important to consider the specific application when choosing between copper-wire and aluminum-wire motors, and to ensure that the chosen motor is suitable for the required load and temperature conditions.

Then, what pumps can aluminum wire motors be used in?

As mentioned before, some low-power and low-load water pumps can use aluminum wire motors without causing significant impact, such as:

-Common household water pumps

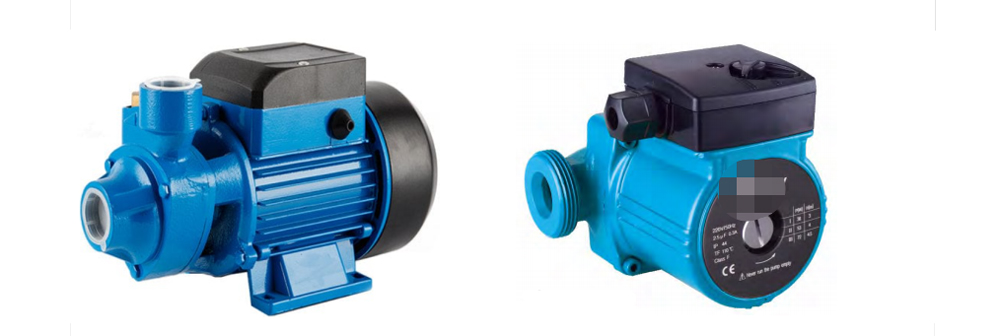

Some low-power household water pumps, such as circulator pump and QB peripheral pumps, typically only require low power and flow, making them suitable for use with aluminum wire motors.

-Small garden pumps

These pumps typically runs intermittently such as watering or sprinkler irrigation from time to time, which requires less durability than common continuously working pumps.

-Pond pumps

Some small pond pumps with less than 100W can also use aluminum wire motors, such as for circulating and filtering pond water.

Please note that while these pumps can use aluminum wire motors, copper wire motors may provide higher efficiency and better durability. Therefore, for high-load or long-term applications, it is recommended to choose copper wire motors to ensure better performance and reliability.

It is worth noting that there is few difference in water pump performance between using aluminum wire motors and copper wire motors, only differences in temperature rise, conductivity, and durability of the motor. While there may not be a noticeable difference in the short term, there can be a significant difference in performance for harsh conditions or long-term use.

How to distinguish aluminum motor from copper motor?

If buyers ask for aluminum motor or the manufacturer mentioned the motor wire at the very beginning, then it’s Ok that you’ve been noted about the pump configuration.

Unfortunately, some manufacturers have been known to falsely advertise their motors as copper wire when they are actually made with aluminum wire. This can be a problem for consumers, as aluminum wire motors may not perform as well or last as long as copper wire motors.

To determine whether a motor is made with copper or aluminum wire, you can ask the manufacturer directly. You can also look for visual differences between the two types of wire, such as the color (copper wire is typically reddish-brown, while aluminum wire is silver) or the thickness(Aluminum winding size needs to be increased to accommodate and offer the same conductance as copper winding).

In conclusion, choosing the right motor for your water pump is crucial for ensuring optimal performance and longevity. While copper wire motors are generally the superior choice for high-performance pumps, aluminum wire motors can be a cost-effective option for low-power and low-load applications. It is important to consider the specific application and load requirements when selecting a motor, and to be aware of false advertising from manufacturers who claim to use copper wire when they are actually using aluminum wire. By making an informed decision, you can ensure that your water pump operates efficiently, reliably, and for a long time.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS