+86 13816508465

Jan. 25, 2024

Submersible pumps are widely used for various applications such as drainage, irrigation, and sewage pumping. To optimize their performance and ensure smooth operation, some accessories are commonly utilized. In this blog, we will explore some of the most common submersible pump accessories and discuss their functions and significance.

NO.1——Float Switch

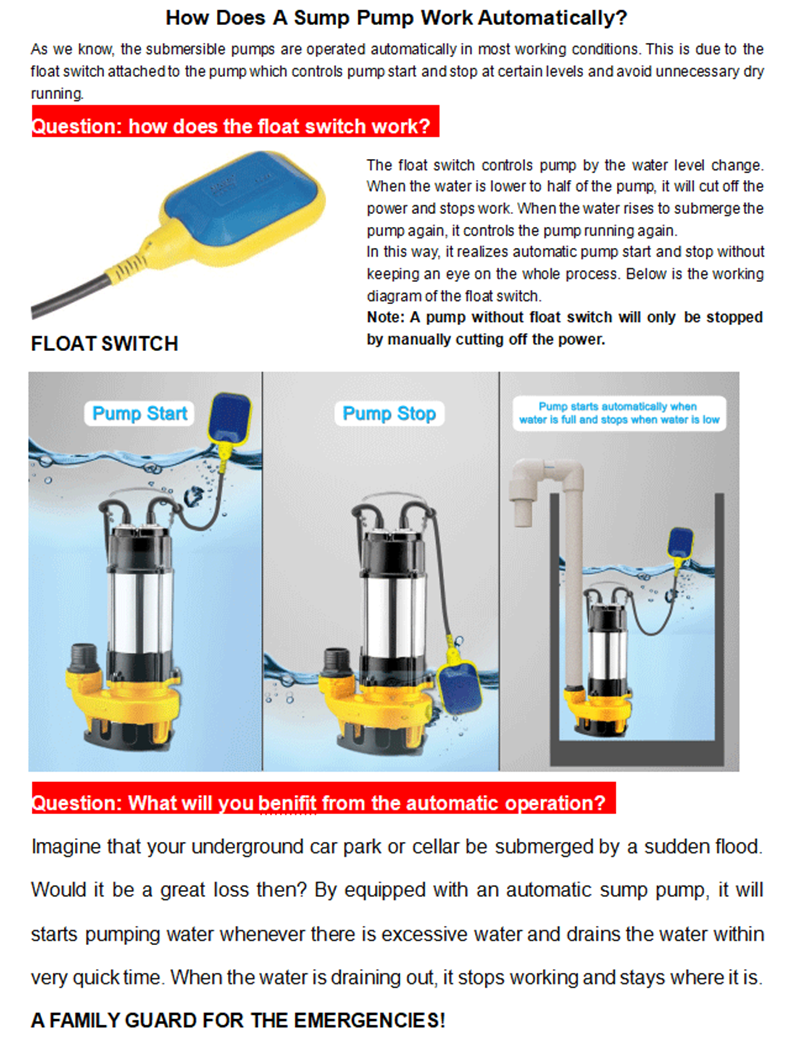

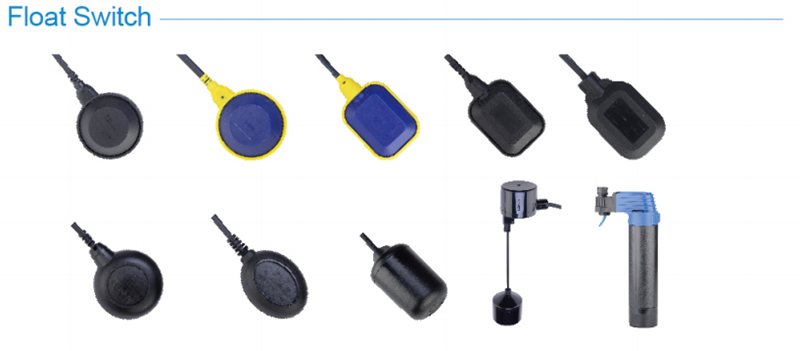

The float switch is a crucial accessory that helps control the pump's operation automatically. It consists of a buoyant float attached to a lever arm. As the water level rises, the float also rises, triggering the switch to activate the pump. When the water level drops, the float descends, turning off the pump. The float switch ensures efficient water level management and protects against dry running, preventing motor damage. See how it works in a sump pump.

Apart from the buoyant float switches, there are other types of float switches available for specific applications. For instance, the vertical float switch is designed for use in limited working spaces and lower water levels. These switches provide flexibility in installations where a traditional float switch may not fit or operate optimally.

NO.2——Check Valve

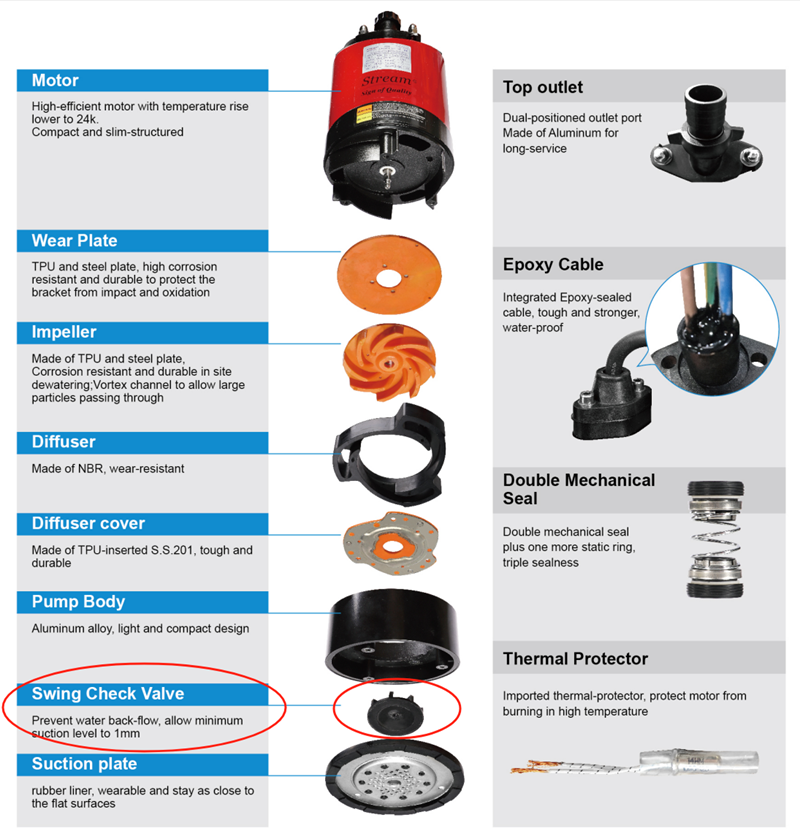

A check valve, also known as a non-return valve or one-way valve, is used in a sump pump system to prevent the backflow of water from the discharge pipe back into the sump pit or water source. Its primary function is to ensure that water flows in one direction, typically from the pump to the intended outlet, while preventing reverse flow.

By using a check valve in a sump pump system, it helps maintain the intended flow direction and ensures efficient operation of the pump by preventing the loss of pumped water and maintaining the prime of the pump. In a typical structure of a submersible puddle pump, a check valve is built to ensure the minimum water residue after pump stops.

NO.3——Hoses and Pipes

Hoses and pipes are essential components that connect the submersible pump to the discharge point. Designed to work with most sump pumps, the flexible hoses is combined with the sump pump to pump water from the water source directly. Flexible and sturdy water hoses with proper diameter and length are preferable for efficient water flow. Rigid pipes may be used for more permanent installations. Proper selection and installation of hoses and pipes are vital to minimize friction loss and ensure optimal pump performance.

NO.4——Outlet Fittings

Outlet fittings play a crucial role in connecting the pump discharge to the discharge pipe or hose in a submersible pump system. These fittings, including elbows, tees, and adapters, are commonly referred to as outlet hose connectors. Their primary function is to establish a secure and reliable connection between the pump and the discharge pipe or hose.

Outlet fittings are designed to ensure efficient water transfer by directing the flow in the desired direction. They help prevent leaks, minimize pressure loss, and maintain the overall performance of the submersible pump system. With a properly installed outlet fitting, water can be effectively transported from the pump to the desired location.

Different materials are available for outlet fittings, including plastic, cast iron, brass, and others. The choice of material depends on factors such as the application, the type of fluid being pumped, and the required durability and corrosion resistance. Each material has its own advantages and may be selected based on specific requirements and environmental conditions.

NO.5——AUTO-Coupling-System

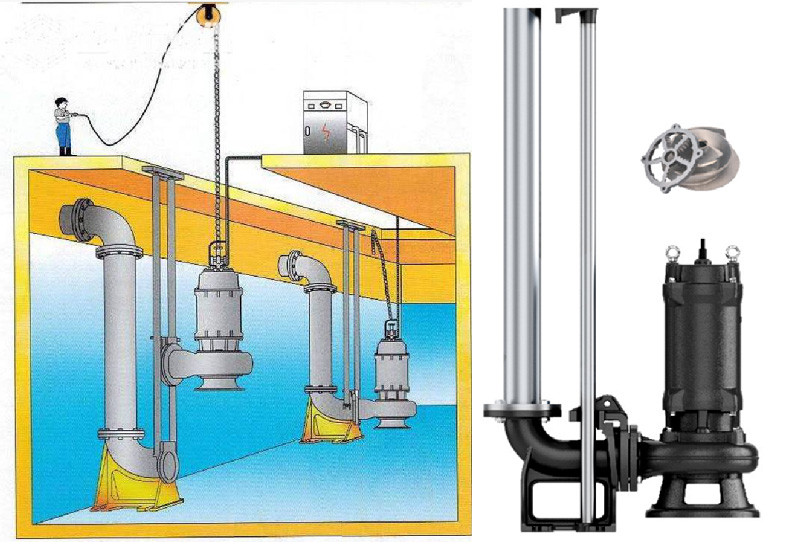

The automatic coupling system is a mechanism used in submersible sewage pumps for automatic connection between the pump's discharge flange and the outlet pipe system. It consists of the pump's discharge flange, an additional coupling flange, and the inlet flange of the outlet pipe seat.

The automatic coupling system is primarily used in sewage pumps installed below the liquid level, where water quality is poor and direct access for maintenance is challenging. It is designed to facilitate maintenance by providing an automatic interface for quick and easy connection between the pump and the outlet pipe system.

The auto-coupling system enables efficient and convenient installation and removal of the pump without requiring manual alignment or disassembly of pipe connections. It enhances operational efficiency and reduces downtime during maintenance or replacement of the submersible sewage pump. This system is commonly used in submersible pumps, particularly for sewage and sludge applications.

Conclusion:

Submersible pump accessories play a vital role in maximizing the efficiency and reliability of these pumps. By understanding and utilizing these common accessories, you can enhance the performance and longevity of the submersible pumping system.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS