+86 13816508465

Pump Knowledge

Jul. 16, 2024

When it comes to submersible pumps, the cable connection is often an overlooked, yet critical component. A poor cable design can lead to devastating water leaks, causing damage to your pump and the surrounding environment.

To ensure a complete watertight seal, attention should be paid to multiple layers of protection:

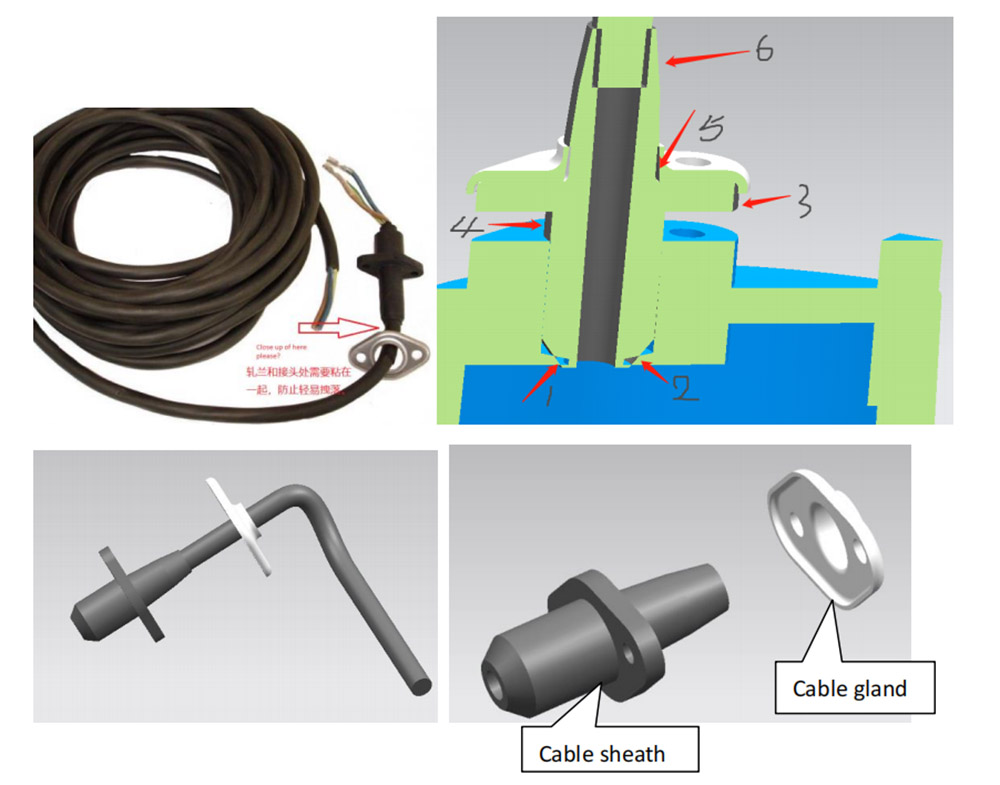

1.Advanced Cable Gland Design

Robust Strain Relief: Heavy-duty strain relief prevents cable damage and loosening over time, maintaining a tight seal.

Specialized Gaskets: High-quality, chemically resistant gaskets create a secure, water-resistant barrier.

Precise Tolerances: Strict manufacturing tolerances guarantee a perfect fit between the cable, gland, and pump housing.

2.Certified Power Cable:

In most countries, VDE (Verband der Elektrotechnik) certification is the standard for power cables used in submersible pump applications. VDE certification ensures the cable meets rigorous safety and performance standards.

However, some regions, like Australia, have additional certification requirements, such as the SAA (Standards Association of Australia) mark. If your pump will be installed in an area with specific cable certification needs, it's important to choose a cable that is approved for use in that location.

Using a certified power cable that is appropriate for the intended environment gives you the assurance that the cable connection will maintain its watertight integrity over the long term.

3.Customized Cable Wiring:

For an extra layer of protection, the pump can be outfitted with epoxy glue-sealed cables. The epoxy creates a solidified, leak-proof barrier around the individual cable wires, so that even if the outer cable sheath is damaged, water cannot infiltrate the pump's interior.

This customized wiring approach provides a double guarantee against water leaks. If the cable is somehow compromised, the epoxy seal will still prevent any moisture from reaching and potentially damaging the pump's motor or other sensitive components.

4.Special Warning Signs and Accessories:

Many users make the mistake of lifting submersible pumps by the cable, which can lead to cable wear, damage, and eventual leaks. However, this practice is strictly prohibited by IEE (Institution of Engineering and Technology) safety regulations.

To proactively address this issue, a clear warning sign on can be put on pumps, advising users to never lift the pump by the cable. Instead, it is recommended using a dedicated lifting rope or chain accessory, which eliminates any risk of cable-related failures.

These simple but important safety measures help ensure your pump is installed and operated in a manner that preserves the integrity of the cable connection and prevents costly water damage down the line.

This meticulous attention to details means you can have complete confidence in the integrity of a pump cable connection. No more worrying about costly leaks or water damage - just reliable, long-lasting performance.

Choose a brand that prioritizes leak prevention with every aspect of their pump engineering. Contact us today to learn more about our superior pump process that ensure pump quality and reliability.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS