+86 13816508465

Apr. 08, 2024

Water pumps are an essential component of many systems that rely on the movement of fluids(mostly water), from residential water supply, irrigation systems, HVAC systems to industrial processes and power plants. Properly controlling water pumps is essential to ensure that they operate efficiently, reliably, and sustainably.

In this article, we will explore the 4 common types of water pump control that are used in household water supply. They are including flow control, pressure control and variable frequency control. We will discuss the working principles, benefits and key considerations that should be taken into account when selecting each control method.

NO1 Flow Control

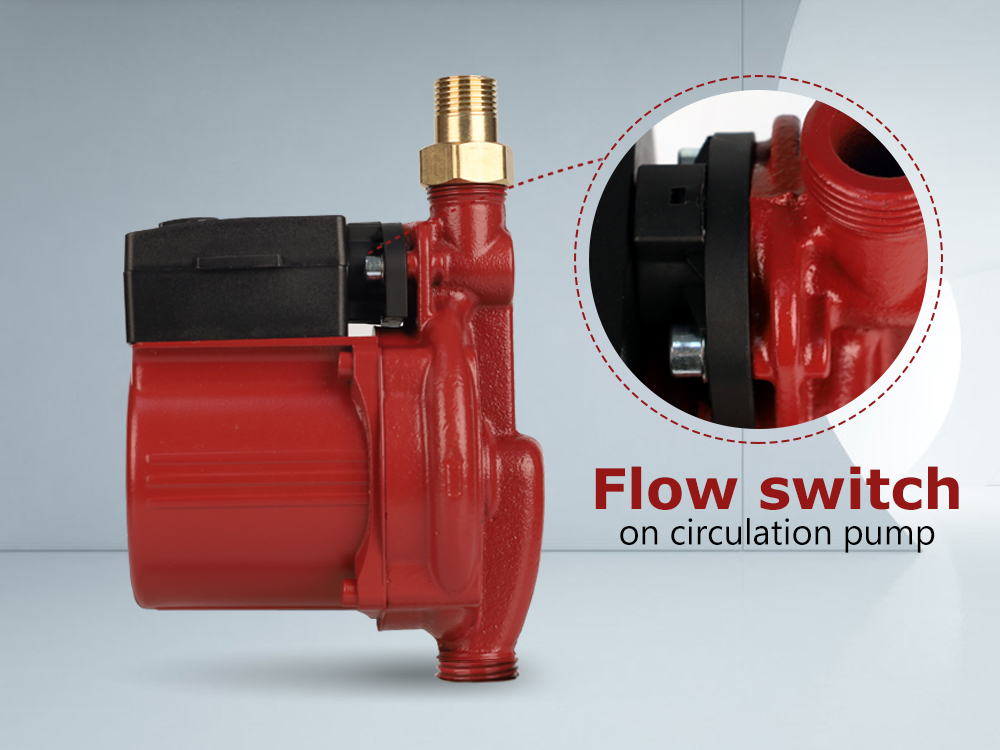

The flow control is the most traditional control method. A pump under flow control will start and stop automatically based on the flow rate. It is often realized by a flow switch.

Working principle: The flow switch detects the changes of flow rate and sends a signal to start or stop the pump based on pre-determined flow rate thresholds.

It works to maintain the consistent flow rate in the system and helps to optimize the pump performance and prevent it from running unnecessarily, which can save energy and reduce wear and tear on the pump.

Overall, flow switch can be a useful tool to control the operation of a water pump in certain situations, particularly where maintaining a consistent flow rate is important. However, it is important to consider the potential disadvantages of flow switches as well, such as their sensitivity to changes in flow rate and their limited accuracy. Actually, they can be used in conjunction with other control devices, such as pressure switches or level sensors, to provide a more comprehensive system.

NO2 Pressure Control

A pump under pressure control will start when water pressure drops and stop when water pressure rises. Normally a pressure switch will control the pump through this way.

Working principle: A pressure switch has preset with a starting pressure value and a stopping pressure value. It turns on the pump when the water pressure falls below the starting pressure and turns off the pump when the water pressure reaches to the stopping pressure.

In many situations especially for the municipal water supply system, the water pressure is varying from morning to evening time. A pump controlled by mere pressure is not stable and will start and stop frequently which leads to troublesome problems.

NO3 Pressure and Flow Integrated Control

An electronic pressure switch is combined by both pressure sensor and flow switch which is the most popular devices for household water booster pumps.

Working principle: Under the dual control, pumps starts when the water pressure drops (taps opening) and stops only when the water flow is 0 (taps closed).

It can replace completely the traditional pump control system composed of pressure switch, pressure tank and check valve, etc. And it can stop the water pump in case of water shortage to prevent it from dry running.

This control solves most problems in household applications and has been the most popular ways for common booster pumps. But due to its pressure limit, it is not suitable for high pressure applications when there are too many taps running together and the water pressure changes greatly.

NO4 Variable Speed Control

The water pump controlled by various speed has applied the variable frequency drive (VFD) technology, which is also called frequency conversion. It is a device used to control the speed of the pump motor, allowing the pump to operate at different speeds depending on the needs of the system.

Working principle: The VFD controller itself is equivalent to a microcomputer, which can handle many feedback signals. The start and stop of the water pump also rely on pressure sensing. Output a frequency value to the motor under poor conditions. If the actual frequency is lower than 50hz, the motor will run slowly, and the pressure will be stabilized by changing the frequency value. If the water consumption is large, it will run fast. if the water consumption is small, it will run slowly, and finally it will stop when no water is used. .

The frequency conversion automatic water pump must be realized by combining the sensor with the frequency conversion speed controller and the constant pressure water supply module. The cost of the variable frequency automatic booster pump is higher than that of the above types, but it has absolute advantages in the comprehensive water experience, and also helps a lot to save energy and improve the efficiency of the pump.

The water supply and drainage of general real estate and public places are automatically controlled by frequency conversion.

Anyway, When choosing between the different pump control methods, you should consider the specific needs and requirements of your application. Factors to consider may include the type of pump, the volume and pressure of the water being pumped, the water sources, and the budget available.

If you are not sure about what pump to use, please contact us and we will be happy to help on that.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS