+86 13816508465

Pump Introductions

Mar. 11, 2024

Stream, sign of quality.

This is not just a slogan, but a principle that we adhere to during our pump manufacturing.

Normally we follow up the process of IQC(incoming quality control), PQC(process quality control), OQC(outgoing quality control).

Have a close look at what we do before a pump is delivered

IQC:

For material incoming quality control, we sort out the raw materials into standard components, special spare parts and key motor parts.

STANDARD COMPONENTS includes:

Mechanical Seal, Bearing, Fan, Fan Cover, Venturi Tube/Diffuser, Bolts.

SPECIAL COMPONENTS includes: impeller, casting ,capacitor

MOTOR PARTS includes: Stator housing, stator, rotor

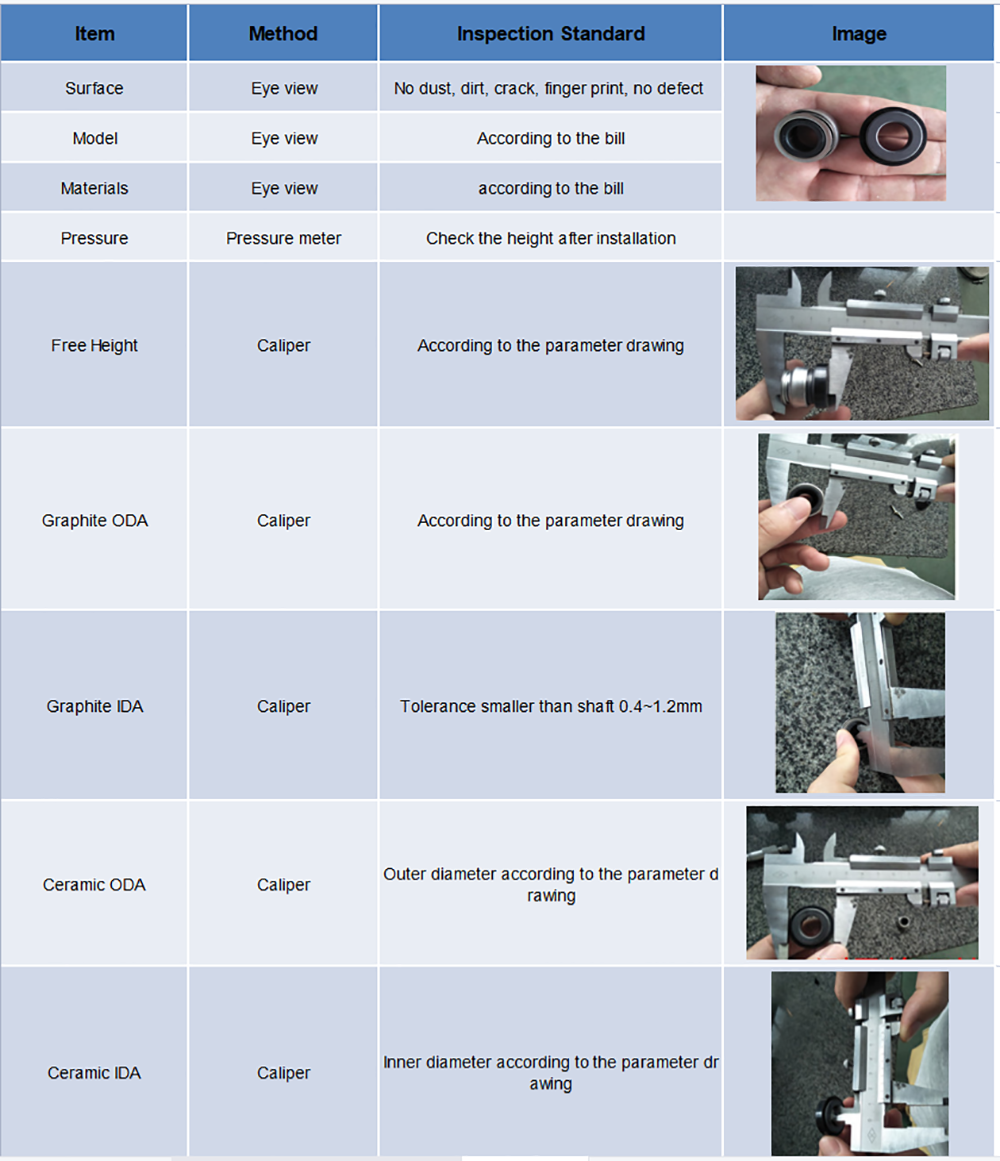

Take Mechanical Seal as example, we do inspection from below points.

Bearing part:

Inspection Item:surface, inner diameter, outer diameter, height

Method: eye view, inner diameter gauge, micro-calliper, calliper

Standard: no defect, right size.

FAN Part:

Inspection item: model, surface

Method: eye view

Standard: right model, surface clean, no shrinkage, no dirt, etc

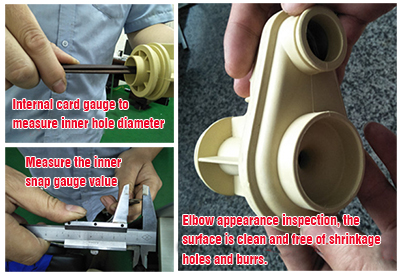

Diffuser Part Inspection Item: Surface,diameter,specification Method: Visual,vernier caliper,drawing Standard:Surface clean,no shrinkage,no burrs,consistent with the drawing |  |

VENTURI Inspection Item:appearance,clean,inner diameter Method:Visual,inner caliper,vernier caliper Standard:model correct,appearance clean,drawing |  |

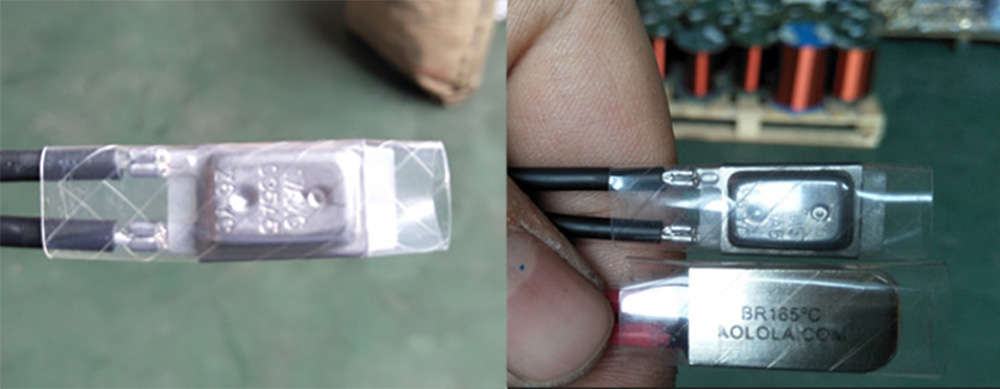

Thermal Protector:

Inspection Item:specifications

Method:visual, temperature test, current test

Standard:17AM/140℃(35A5)17AM/120 ℃(31A5)21AM/165 ℃

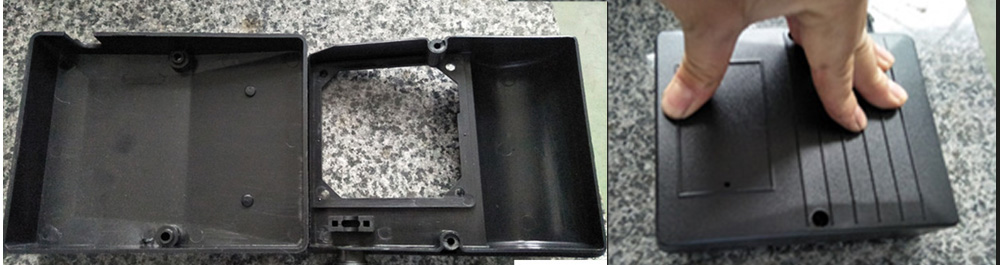

Terminal Box:

Inspection Item:appearance, strength

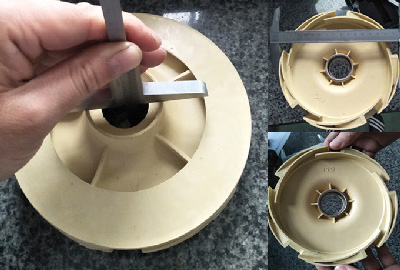

Impeller

Inspection Item: surface, specifications, outer dia, flow channel

Pump Body

Inspection Item:size, appearance, inlet inner dia, plug screw size

Pump Bracket

Inspection Item:surface, spigot specification, bearing, mechanical seal

Capacitor

Inspection Item:size, capacity(μF)

The motor is a crucial component and the heart of a pump that cannot fail. At Stream, we take our motors very seriously. We heat our stator housing to 140 degrees and shrink them on to the stator to eliminate the chance of movement that can lead to failure.

Stator Housing

Inspection Item:surface, specifications, inner dia.

Motor Rotor

Inspection Item: size, appearance, dia, bearing spot, mechanical seal spot, impeller spot, shaft distance, length, concentricity.

Motor Stator

Inspection Item: surface, outer dia., stator length, inner dia.

The above are the main steps of raw materials incoming quality control.

As for process control, we execute the inspections from below parts:

Assembly Inspection

Performance Inspection

Pressure Tightness Inspection

Packing Inspection

ASSEMBLY INSPECTION

Spare parts double inspection, castings and pump body double inspection,

Water leakage test, noise test

PRESSURE TIGHTNESS INSPECTION

PUMPING TEST

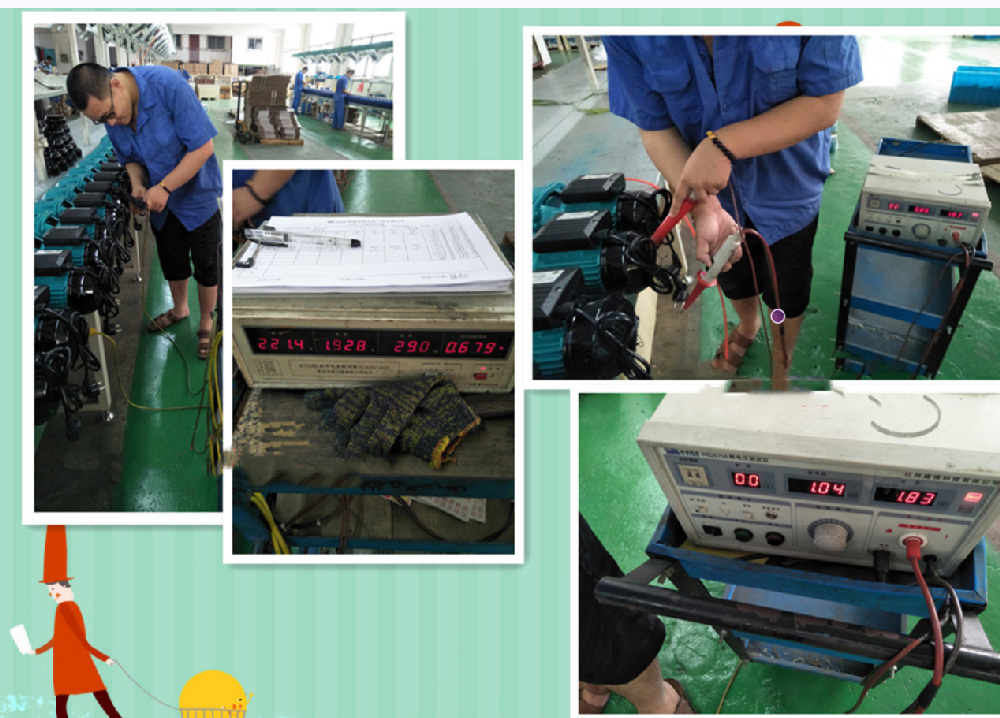

PERFORMANCE INSPECTION

PACKAGE TEST

Inspection Item:painting color/ surface / spare parts/ operating/ voltage test

Method of Inspection:visual/ voltage testing equipment/ parameter equipment

Criteria of Inspection:consistency with the requirements of the painting color and spare parts/ painting even and no varnished/ pump operating without noise, viberation or breakage/ qualified unload current and power rate

1~ 1800v/1s、3~2100v/1s without breakdown

Special Test By Requests

LEAKAGE TEST for mechanical seal

Inspection Item:Mechanical seal

Standard:continuous pumping without leakage

SALINE TEST for anti-rusting castings

Inspection Item:anti rust casting performance in salty water

You can depend on Stream for quality and reliability. What you concern, we solve it for you.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS