+86 13816508465

Pump Introductions

Nov. 06, 2024

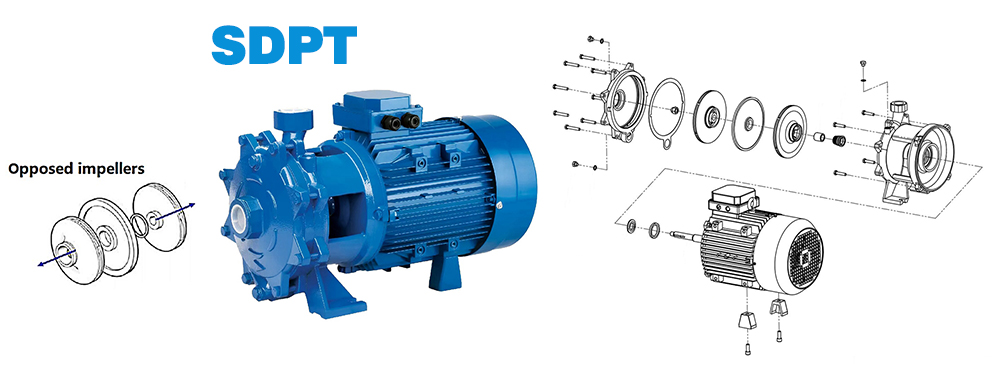

Centrifugal pumps are essential across many industries, providing dependable fluid transfer for residential, commercial, and industrial applications. While single-stage centrifugal pumps are adequate for most tasks, twin-impeller centrifugal pumps offer higher lifting pressure, making them ideal for applications demanding greater power and efficiency. Today we're introducing our SDPT twin-impeller centrifugal pump, designed to deliver outstanding performance and reliability for demanding tasks.

A single-stage centrifugal pump has one impeller, which provides moderate pressure, making it compact and effective for tasks with lower pressure requirements. In contrast, twin-impeller centrifugal pumps utilize two impellers in sequence to pressurize fluid across stages, creating higher head pressure.

The SDPT pump goes a step further with its back-to-back impeller configuration. This unique design minimizes axial thrust by balancing forces within the pump, eliminating the need for separate balancing devices. This structure allows the SDPT to achieve high pressure and flow capacities, making it a reliable solution for applications such as firefighting systems, high-rise water supply, and extensive irrigation systems.

Close-Coupled Monoblock Design: The pump and motor are closely coupled, sharing a common shaft, which reduces space requirements, simplifies installation and minimizes alignment issues.

Back-to-Back Impeller Structure: Unlike serial impeller setups, which maximize pressure by arranging impellers in the same direction, the twin-impeller centrifugal pump features a back-to-back impeller structure. This design effectively balances axial forces, reducing strain on the shaft and bearings, minimizing vibration and noise, and extending the pump's operational lifespan. This natural balance reduces the need for additional thrust-balancing devices and helps keep maintenance needs low.

Enhanced Durability: With options for durable seals and materials, such as stainless steel and Viton, these pumps are well-equipped to handle harsh environments, reducing wear and prolonging service life.

Lower Maintenance Needs: The balanced design and resilient construction of twin-impeller centrifugal pumps lead to lower maintenance costs and greater efficiency over the long term.

Twin-impeller centrifugal pumps are ideal for scenarios requiring high pressure and durability, such as:

Water supply for high-rise buildings and large commercial facilities

Extensive agricultural irrigation for long-distance and high hills.

Industrial cooling and heating systems

Firefighting systems requiring strong, continuous water flow

Q: What's the typical lifespan of a twin-impeller centrifugal pump?

A: With proper use and routine maintenance, a quality twin-impeller pump can last 10-15 years or more.

Q: Can twin-impeller pumps handle abrasive or solid-laden fluids?

A: Generally, twin-impeller pumps are designed for clean water. For solids or abrasives, another pump type may be more suitable.

Q: How do I know if I need a single-stage or two stage (twin-impeller) pump?

A: For general pumping tasks like filling a tank, firefighting, or running a sprinkler system, a single-stage pump is typically more affordable and efficient. However, if you need to pump to a high-elevation tank or across a long distance, a twin-impeller (two-stage) pump is a better choice, as it provides the higher pressure needed for these demanding applications.

Twin-impeller centrifugal pumps are a reliable choice for high-pressure applications. Built to last and designed for efficiency, these pumps meet ISO 9908 standards and come with advanced structural and material options to match various demanding applications. For tailored advice on selecting the right pump for your needs, reach out to our team of experts.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS