+86 13816508465

Product Q&A

Jun. 05, 2024

Deep well pumps are an essential solution for accessing water from the depths of the earth, particularly where surface water is scarce or contaminated. These vertical, multistage centrifugal pumps are designed to be submerged in wells, making them the perfect choice for agricultural irrigation, industrial water supply, and residential use. However, selecting the right deep well pump for your specific needs is crucial to ensure efficient water extraction and longevity of the system. In this comprehensive guide, we'll explore the key factors to consider when choosing a deep well pump, providing you with the knowledge to make an informed decision for your water extraction requirements.

1.Understanding the deep well pumps

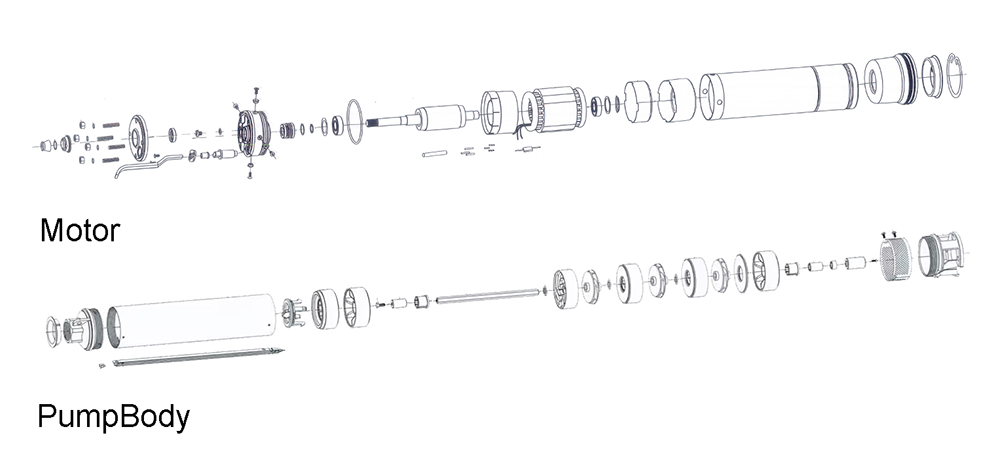

Deep well pumps are unique in their integration of the electric motor and pump into a single, compact unit. This design allows the pump to be submerged directly in the well water, leading to a variety of motor types, including dry, semi-dry, oil-filled and water-filled structures. Understanding the differences in these motor types is the first step in selecting the right pump for your application.

1.1 Explosive View

1.2 Different motor types:

The motor types of deep well pumps are determined by their cooling and protection mechanisms, which are essential for their operation in submerged environments. Here's a basic understanding of the different motor types:

Dry Type Motors: These motors are designed with a sealed structure that prevents water from entering the motor. They are cooled by the air or another gas that is circulated within the motor housing. Dry type motors are suitable for clean water sources and are generally more cost-effective.

Semi-Dry Type Motors: As the name suggests, semi-dry motors are a hybrid between dry and oil-filled motors. They allow a small amount of water to be present around the motor to aid in cooling, but they are not fully submerged. This type of motor offers some protection against water ingress and is suitable for slightly contaminated or dirty water sources.

Oil-Filled Type Motors: In this type, the motor's internal components are submerged in oil, which serves as both a coolant and a lubricant. The oil-filled motor is sealed to prevent the mixing of the coolant oil with the surrounding water. These motors are ideal for applications where the water may be contaminated with abrasive particles or chemicals, as the oil provides an additional barrier against wear and corrosion.

Water-Filled Type Motors: These motors are filled with water as the cooling medium, which is in direct contact with the motor's internal components. Water-filled motors are typically used in clean water sources and are designed to handle the challenges of continuous submersion. They are built to withstand the pressure and corrosive effects of long-term water exposure.

Each motor type serves a specific purpose and is chosen based on the conditions of the well and the quality of the water being pumped. For instance, dry and semi-dry motors might be preferred in wells with clean water to prevent contamination, while oil-filled and water-filled motors may be chosen for their enhanced protection and cooling capabilities in more challenging environments.

2.Matching Pump Capacity to Water Source Yield

The capacity of the deep well pump must be aligned with the actual yield of the well to avoid over-pumping, which can damage the pump, filter screen, and well integrity. It's essential to assess the maximum allowable extraction volume of your water source to ensure that the pump's capacity is appropriately matched, neither exceeding nor falling short of the required output.

3.Considering The Well Casing Diameter

When selecting the appropriate diameter for a deep well pump, it is essential to consider the well casing diameter to ensure efficient water extraction and a long-lasting pump system. The pump's diameter must be carefully chosen to fit within the well casing, maintaining a critical balance between the pump's size and the well's dimensions.

Different Well Diameter Choices:

The choice of well diameter can vary widely based on the specific application and the desired output of the well. Here are some common well diameter choices and their implications for pump selection:

Small Diameter Wells (2 to 4 inches): These wells are typically used for domestic water supply or small-scale irrigation. The corresponding deep well pumps are smaller and have lower flow rates but are ideal for these applications due to their precision fit and efficient operation.

Medium Diameter Wells (4 to 8 inches): This range is suitable for larger agricultural operations or industrial uses where higher water volumes are required. The pumps for these wells are designed to handle increased flow rates while maintaining efficiency.

Large Diameter Wells (8 inches and above): Large diameter wells are often used in commercial or municipal water supply systems. The pumps for these wells are robust and capable of high flow rates and may include additional features to handle the increased water volume and pressure.

Notes on the applications:

When selecting the pump diameter, it is also important to consider the well's construction, including the materials used for the casing and the presence of any filters or screens. The pump must be compatible with these elements to ensure proper water extraction and to prevent damage to the well system.

In conclusion, the selection of the deep well pump diameter is a critical decision that affects the performance, efficiency, and longevity of the water extraction system. By carefully considering the well casing diameter and the specific requirements of the application, users can choose a pump that will provide reliable and efficient service for years to come.

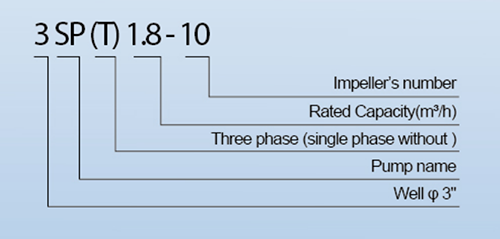

4.Determining the Pump Specification and Model

Once the water source's yield and well conditions are understood, the specification and model of the deep well pump can be determined. This step is crucial for establishing the appropriate structure for the water source well and ensuring that the pump meets the specific demands of your water extraction needs.

Here is a general pump model that illustrates the pump main specifications to be selected.

Other key factors to be considered:

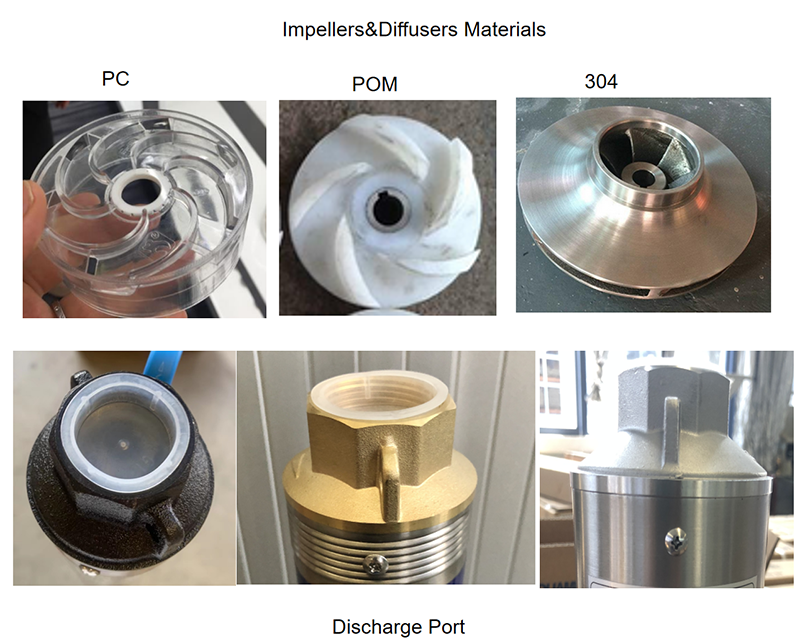

Construction Materials:

The choice of materials for the pump's construction significantly impacts its durability and performance. The pump casing, impellers, diffusers, and ports should be made from materials that can withstand the corrosive nature of the well water and the rigors of continuous operation. Common materials include stainless steel which offers excellent resistance to corrosion, and plastic which is more cost effective. The selection of materials must align with the supplier's offerings and be suited to the specific working conditions of the well.

Control Mode:

Deep well pumps can be controlled in various ways, each with its advantages and considerations. Built-in capacitor control is a traditional method that simplifies the installation process. External on-off control boxes offer more flexibility and can be easily integrated with automation systems. Functional control cabinets provide advanced features such as remote monitoring, fault diagnostics, and energy management, which can enhance the overall efficiency and reliability of the pump system.

Cable Length:

The length of the power cable supplying the pump must be carefully considered to ensure a secure and efficient connection to the power source. The cable length should account for the depth of the well, with enough additional length to accommodate any potential adjustments or future well deepening. It is also important to select a cable type that is rated for the specific voltage and current requirements of the pump and is suitable for submersion in water, typically with waterproof and abrasion-resistant qualities.

Additional Considerations:

Efficiency Ratings: Look for pumps with high efficiency ratings to reduce energy consumption and operating costs.

Service Factor: A pump with a higher service factor can handle occasional overloads without damage, providing added resilience.

Bearings and Sealing Systems: High-quality bearings and advanced sealing systems are crucial for the pump's longevity, especially when operating in challenging conditions.

Maintenance Accessibility: Choose a pump model that allows for easy maintenance and part replacement to minimize downtime and service costs.

By meticulously considering these factors and working closely with knowledgeable suppliers or engineers, you can select a deep well pump model that is perfectly suited to your water extraction needs. The right pump will not only meet your current demands but also adapt to future changes, ensuring a reliable and efficient water supply for years to come.

5.Considering Total Head Loss

When selecting a deep well pump, it's important to account for the total head loss, which is the energy required to transport water from the pump head to the surface storage tank or water tower. The pump's diameter, head lift (number of stages), and power should be chosen based on this head loss, ensuring that the pump can effectively move water without causing excessive wear or operational issues.

Conclusion

Choosing the right deep well pump is a critical decision that affects the efficiency, reliability, and longevity of your water extraction system. By carefully considering the water yield, well diameter, pump head placement, and total head loss, you can select a pump that meets your specific needs and delivers a steady, dependable supply of water from your deep well.

At Stream Pumps, we offer a wide range of deep well pumps designed to cater to various applications and water source conditions. Our team of experts is ready to assist you in making the best choice for your water extraction needs. Trust us to guide you towards a solution that ensures a sustainable and efficient water supply for years to come.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS