+86 13816508465

Feb. 21, 2025

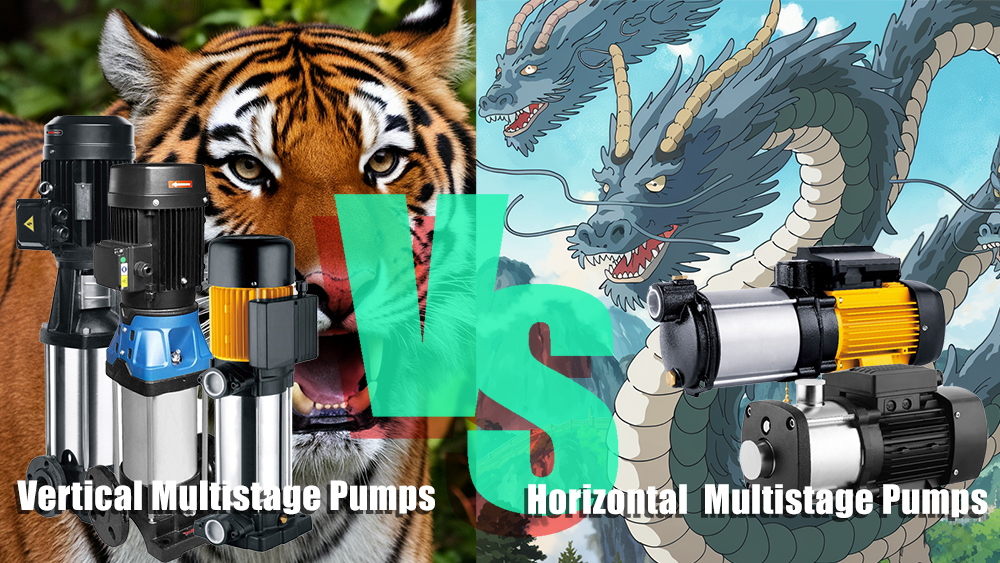

When selecting the right pump for your application, the choice between horizontal and vertical multistage pumps is critical. Both options offer unique advantages, but understanding their differences can help you make the best decision for your needs. This guide explores the key features, applications, and benefits of each pump type to help you choose wisely.

Design and Orientation

Structure: These pumps have a tall, upright design, with multiple impellers stacked vertically.

Space Efficiency: Ideal for installations with limited floor space, such as urban settings or compact pump rooms.

Primarily Used For: Applications requiring high pressure with a small footprint, like skyscrapers or industrial water supply systems.

Structure: Designed with impellers arranged horizontally along a single shaft.

Stability: Better suited for installations with ample space, offering enhanced stability on flat surfaces.

Primarily Used For: Situations requiring high flow rates at moderate pressure, like agricultural irrigation or industrial processes.

Performance Characteristics

Vertical Multistage Pumps:

Pressure: Their design allows for significant pressure generation, making them ideal for tall buildings or systems requiring long-distance water transportation.

Flow: Typically designed for applications where high pressure is more important than high flow.

Horizontal Multistage Pumps:

Pressure: While they can deliver pressure, it’s generally lower than that of vertical pumps.

Flow: These pumps handle a larger flow of water efficiently, making them perfect for systems that prioritize flow over pressure.

Installation and Maintenance

Ease of Installation: It requires less floor space but may need careful alignment during setup.

Maintenance Considerations: Access to components like bearings or impellers can be more challenging due to the vertical arrangement.

Ease of Installation: Need a larger footprint but are easier to install and align.

Simpler Maintenance: A horizontal layout allows for easier access to parts, reducing downtime during repairs.

Applications

High-rise buildings (e.g., skyscrapers).

Boiler feed systems.

Reverse osmosis systems.

Firefighting systems require high pressure.

Agricultural irrigation.

Industrial processes need high flow.

Water treatment plants.

Cooling systems in power plants.

Cost and Energy Efficiency

Cost: May have a higher initial cost due to their compact design and advanced features.

Energy Efficiency: Often more energy-efficient in high-pressure applications.

Cost: Typically more affordable upfront, especially for high-flow, low-pressure systems.

Energy Efficiency: Efficiency depends on the specific application but may be lower than vertical pumps for high-pressure needs.

Choosing the Right Pump

Space Availability:

Choose vertical pumps for tight spaces.

Opt for horizontal pumps if you have sufficient room.

Pressure vs. Flow:

Vertical pumps for high-pressure applications.

Horizontal pumps for high-flow systems.

Maintenance Requirements:

Horizontal pumps are easier to maintain.

Vertical pumps may require more effort but offer longer lifespans in demanding conditions.

Application Type:

Evaluate your industry needs, such as irrigation, industrial use, or building water supply.

Both horizontal and vertical multistage pumps serve vital roles in various industries. By understanding their unique features and aligning them with your operational requirements, you can make an informed choice.

Vertical pumps excel in high-pressure, space-saving scenarios, while horizontal pumps are the go-to option for high-flow applications with easier maintenance. Carefully assess your needs to ensure the best fit for your system.

Target Keywords:

Horizontal vs vertical multistage pumps

Vertical pump benefits

Horizontal multistage pump applications

Choosing the right pump

Pump comparison guide

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS